Products

& Solutions

Products

&

Solutions

&

Solutions

Our Products

Our Solutions

FluidCore Synergy: Liquid Cooling Module for AI Computing

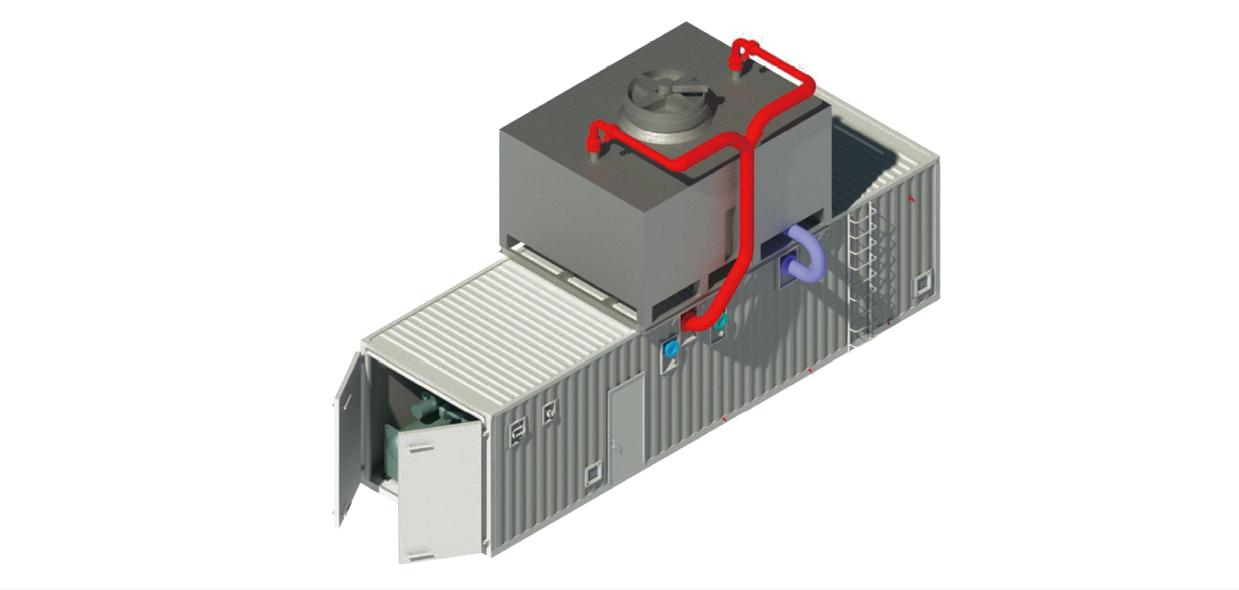

Containerized Data Center Solution

Data Center Energy Efficiency Retrofit

Heating Solutions for Communities and Commercial Properties

Energy Performance Contracting (EPC) in Energy Efficiency

Building/Regional Energy Efficiency Consulting

Smart Building Operation and Maintenance

Integrated PV-Storage-Charging System